Solvent Handler™

A free flowing oxygen scavenging granule developed to control hydrocarbon spills. When the virtually dust-free granule is applied, the spilled material is solidified, vapors are eliminated, and flammability is reduced. The resulting dry granules can be easily swept up with little to no evidence of a spill having occurred. Effective in controlling flammable liquids, hydraulic oils, brake oils, chlorinated solvents, motor oils, residual flammable liquids or sludge left in containers or storage tanks.

Sizes Available

Part#SH-32 | 32oz Shaker Bottle

Part#SH-01 | 1 Gallon Dispenser Bottle

Also Available in our Safety Spill Response Kits

Directions

- Consult SDS for the spilled material to become familiar with its chemical properties and safety and health requirements.

- Select and wear proper personal protective equipment for the spilled chemical.

- Evacuate area as necessary to ensure safety of personnel.

- Eliminate all sources of ignition and ensure that there is adequate ventilation available before applying product.

- Apply Solvent Handler to spill from the upwind side around its perimeter to dike the liquid, working from the outside of the spill toward the center. Completely blanket the spill, eliminating all wet areas.

- Agitate product on the spill area with non-sparking paddle or scrapper, adding additional Solvent Handler as needed to eliminate all wet areas.

- Check vapor elimination, using a vapor detection device.

- Add additional Solvent Handler product until all vapor is eliminated.

- Dispose of neutralized waste in accordance with Federal, State, and Local environmental regulations.

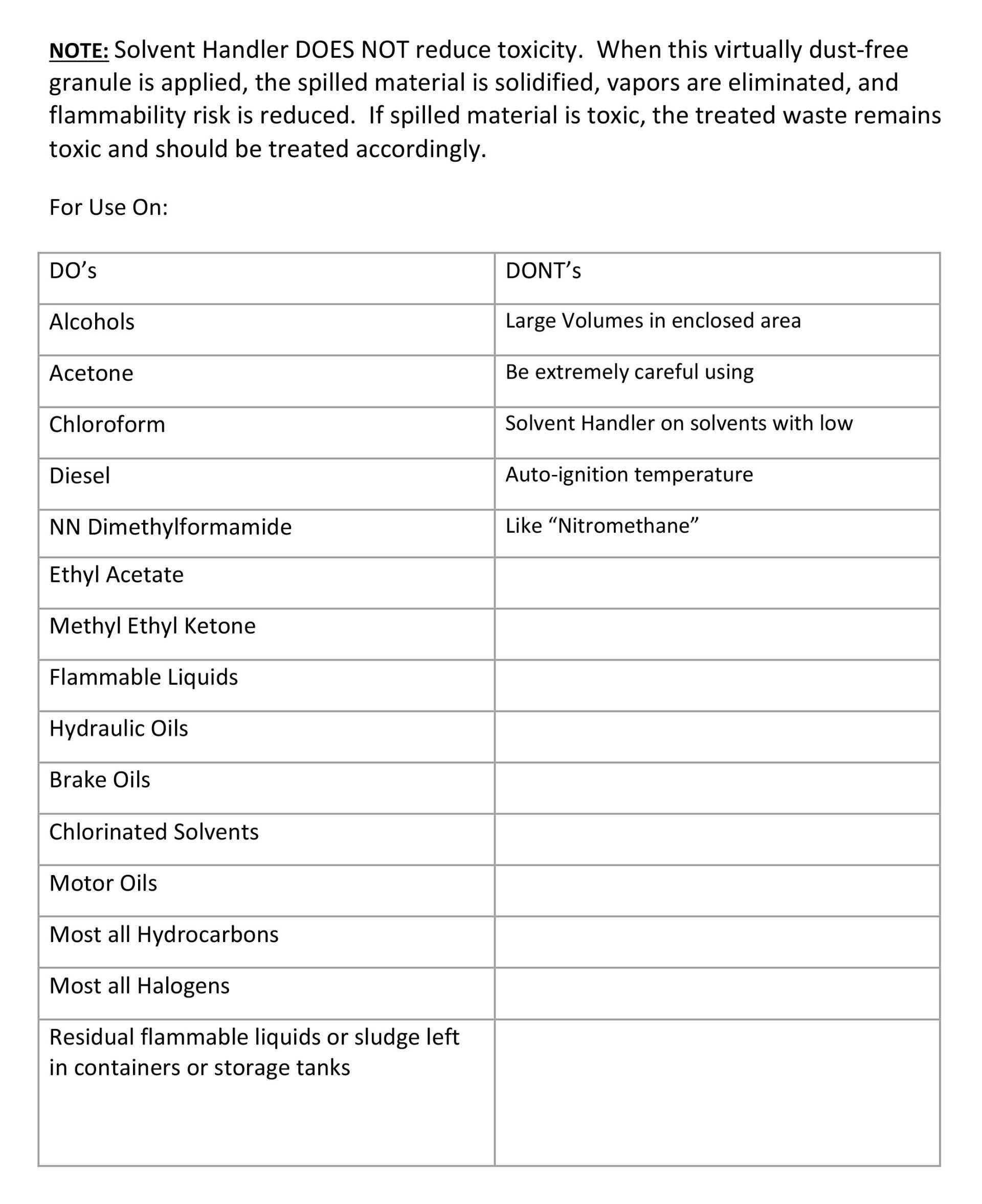

For Use On: