SlideBrite™

The Safest Xylene Substitute Available

S-Mount™ Insures Compatibility and High-Quality Slides Every time

Aliphatic Hydrocarbon

An odorless substitute to Xylene that while gentle on tissue does not make it brittle. No tissue shrinkage or morphology changes. Non-flammable with a flash point of 142°F. Does not need to be stored in a non-flammable storage and no hazardous shipping. Compatible with IHC staining.

Sizes Available

Item# SB-04 l 4 x 1 Gallon per Case l SlideBrite™

Item# SMM-04 l 1 x 120ml (4oz) Dispenser Bottle l S-Mount™

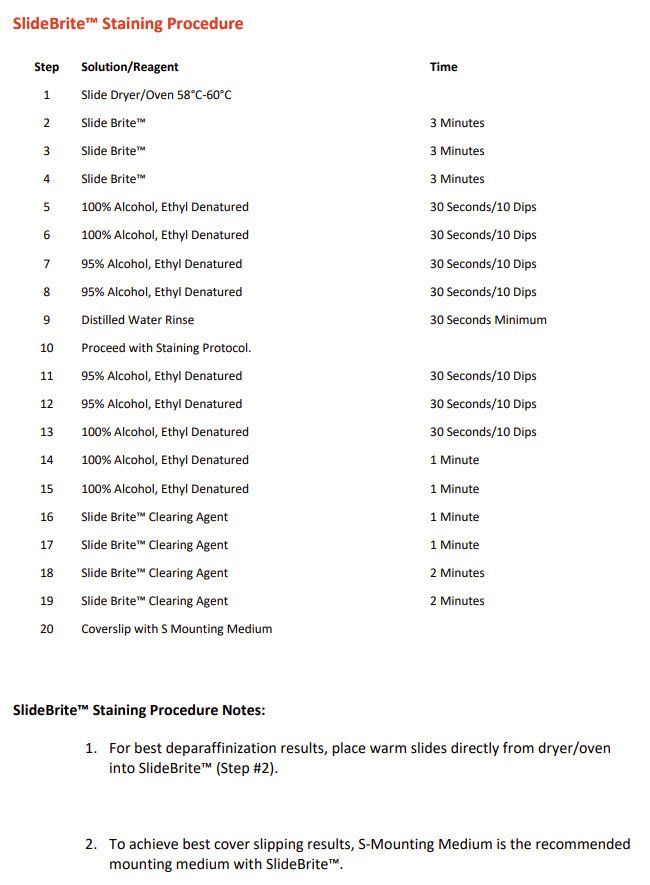

Staining Procedure

- Refer to SlideBrite™ Staining Procedure.

- For best deparaffinization results, place warm slides directly from dryer/oven into SlideBrite™.

- Deparaffinize warm slides thoroughly in three changes of SlideBrite™, 3 minutes each. Hydrate through two changes each of 100% and 95% ethyl alcohols, 10 dips each. Wash well with distilled water. a. See Procedure Notes #1, #2 and #3.

- Proceed with staining protocol.

- Dehydrate in two changes of 95% and three changes of 100% ethyl alcohol. Clear in four changes of SlideBrite™.

- Coverslip with S Mounting Medium a. See Procedure Note #4.

- Test and optimize SlideBrite™ in staining procedures and automated staining systems prior to standard use.

Procedure Notes

- Deparaffinization and clearing steps may require longer timings then xylene.

- Due to absorption rates SlideBrite™ will require more frequent changes compared to xylene.

- Any water contamination will sit on top of SlideBrite™.

- Test SlideBrite™ compatibility with other mounting mediums prior to use. a. If mounting medium is not readily miscible or displays separation it is incompatible with SlideBrite™,

- SlideBrite™ is not recommended for automated coverslippers.

- SlideBrite™ will not remove adhered coverslips as well as xylene.

- Refer to manufacturer’s specifications on the use of SlideBrite™ on all instrumentation.

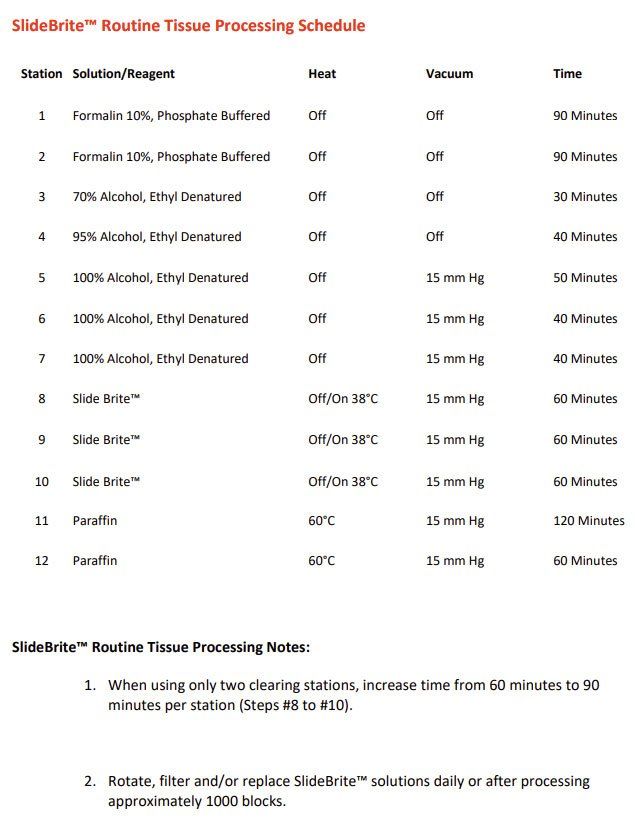

SlideBrite™ Routine Tissue Processing Schedule

SlideBrite™ Staining Procedure